Of all the directions unconventional agriculture is taking in this country, the most interesting may come under the heading of urban farming. For example, take the project that turned up in Monday’s Pioneer Press:

Cub Foods has teamed with a number of out-state Minnesota growers to sell everything from cucumbers to sweet corn in season, but its latest partnership will be even more local and less seasonal.

Through a new agreement with BrightFarms, a New York-based greenhouse company, the supermarket chain will soon deliver St. Paul-grown lettuce and tomatoes to Twin Cities shoppers year-round …

The unlikely location for the groundbreaking was a back lot at JJ Distributing, a Rice Street fruit and vegetable distributor more accustomed to receiving semi-trailers full of California lettuce than urban farming. Nevertheless, [Cub executive Chuck] Lynch and JJ President Jim Hannigan said the BrightFarms greenhouse will be on the cutting-edge of the “buy local” movement.

Cub Foods expects to begin selling its St. Paul-grown produce in the fall.

This produce will be grown hydroponically, a method that requires heavy investment at startup but returns significant savings on operating costs for fertilizer, heat, water, labor and equipment.

350,000 pounds per acre

BrightFarms says the Rice Street greenhouse is expected to produce 350,000 pounds of vegetables and herbs per year, delivered to markets within hours of harvest, at prices comparable to dirt-grown organic produce – all on a footprint less than an acre in size.

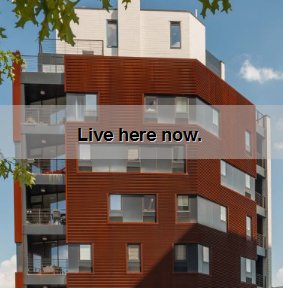

Indeed, the hydroponic methods BrightFarms has adopted can yield so much food from so little territory that the greenhouses needn’t take up any unbuilt land.

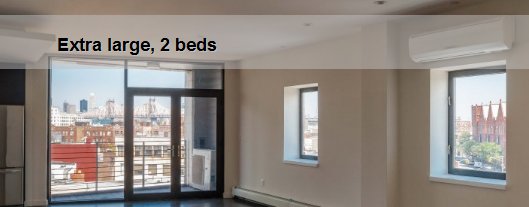

One of its first projects was sited on a barge in the Hudson River; one of its next will be a 100,000-square-foot operation atop an old Navy warehouse in Brooklyn’s Sunset Park.

At about 2½ times the size of the St. Paul project’s 38,000 square feet, the Sunset Park project is said to be the largest urban rooftop farm under development anywhere in the United States, and possibly anywhere in the world.

But maybe not for long.

BrightFarms says it has eight big projects under way with supermarket chains, four of which have gone public with four remaining unnamed for now. (Besides Sunset Park and St. Paul, the other announced location are Bucks County, Pa., and Oklahoma City.)

And there are competitors. In Montreal, Lufa Farms is merging the notion of urban farming with the community-supported agriculture model, selling mixed boxes of produce to subscribers at a price averaging somewhere between $3 and $4 per pound.

Vertical farms for urban settings

On the visionary fringe, perhaps, a company called TerraSphere sells plans and equipment for vertical hydroponic farms in urban settings, with layer upon layer of crops rising floor after floor to the height of seriously tall buildings.

At the moment, the largest urban rooftop farm in America appears to be the Brooklyn Grange, which covers slightly more than an acre atop a century-old industrial building in Long Island City, Queens.

It produces a wider array of food that BrightFarms envisions – salad greens, herbs, carrots, beets, radishes, beans and more – but is decidedly low-tech.

Its crops grow in dirt, some 1.2 million pounds of it, and without a greenhouse roof. In winter, the operators plant clover and other cover crops to control soil erosion, which is a management problem everywhere but rather different in the middle of Brooklyn. You wonder how they ever got a permit.

But they did, and now they’re well on the way to a second, 45,000-square-foot operation in the Brooklyn Navy Yard.

Both the BrightFarms and Brooklyn Grange business models rely on increasing consumer preference for locally grown produce, both for its freshness and for the avoided costs and environmental impacts of the fantastically long journeys a tomato may travel from, say, Sacramento to St. Paul at midwinter.

The BrightFarms CEO, Paul Lightfoot, told the Pioneer Press that this locavore trend is doing to Big Organic what little organic did initially to conventional agriculture: “Demand for local food is eclipsing demand for organic food in most markets. The challenge is that supermarkets can’t get a consistent supply of local foods year-round.”

Time will tell on that point, I suppose, and also on whether BrightFarms can persuade produce shoppers that the flavorless hydroponic tomato some of us may remember is merely the relic of an earlier age in dirt-free horticulture. Speaking personally, I can’t wait to try the new stuff.

BrightFarms got its start advising rooftop growers on setting up their operations, and the case it makes for greenhouse hydroponics over soil-based methods might be compelling even apart from that little problem of hauling up a million pounds of dirt per planted acre.

With either method, production costs per tomato are higher than with regular terrestrial agriculture. But, Lightfoot says, the “system costs” – from planting through shipping to final sale – can be lower because of the transportation savings, the ability to manage growing conditions more precisely, and the smaller outlays required for rent, fertilizers, pesticides, labor and heavy equipment.

An answer to food insecurity?

Hydroponics have an even greater edge on some of those factors, and offer an additional savings in repeatedly recycling the water.

And here I think it must be noted that beyond all those business-competition virtues, hydroponic food production would seem to be inherently scalable and, perhaps, nearly indifferent to location. This may come to matter a lot in a world where so much about the future of food is so uncertain.

The sheer unsustainability of much modern agricultural practice, combined with continued population growth and changing climate regimes, may be moving us toward truly frightening scenarios of scarcity and instability.

So today the hydroponic urban farm may be the method of choice for producing fresh, full-flavored baby arugula in a northern clime at midwinter.

Down the road, it may be needed as a bulwark against famine.